If you have a DIY project that involves cutting sheet metal but lack experience, you can successfully make clean and precise cuts using an affordable jigsaw. While metal cutting demands a different approach compared to wood, a standard jigsaw, equipped with the appropriate blade, can efficiently handle thin sheet metal for various DIY needs. Let's delve deeper into the process.

What jigsaw do I need for cutting metal?

Selecting the proper jigsaw is the first crucial step in cutting metal effectively.

Power and speed

Look for a jigsaw with a minimum of 600 watts of power. Higher power enables faster and more precise cuts. Additionally, opt for a jigsaw with adjustable speed settings, which provide you with more control over the cutting process.

Blade selection

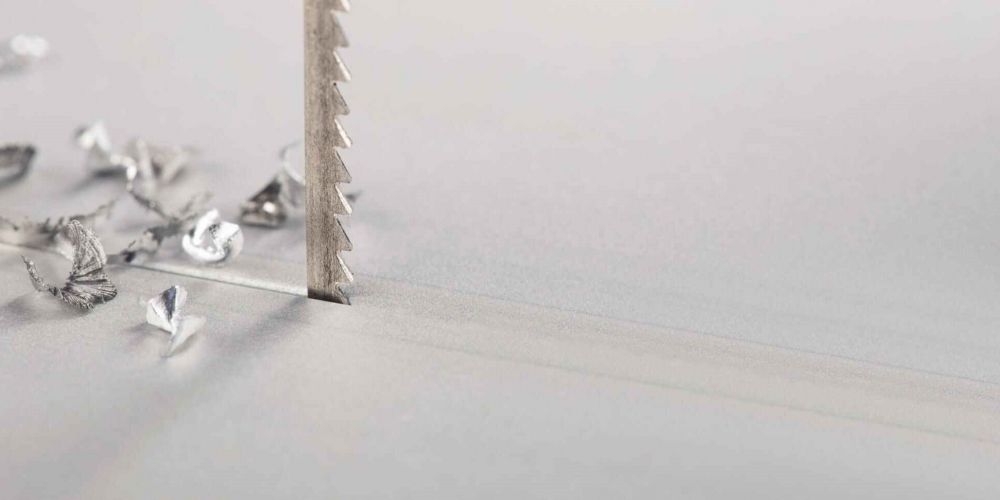

Tungsten carbide blades, often referred to as bi-metal blades, are essential for cutting metal. These blades are incredibly hard and maintain sharpness for extended periods during metal-cutting tasks.

Teeth per inch (TPI)

For most metal cutting applications, a blade with 14 to 24 teeth per inch is ideal. More teeth per inch deliver a finer cut, while fewer teeth remove material more quickly. Moreover, it's essential to choose blades specifically designed for the type of metal you're cutting – mild steel, aluminium, or other alloys each require different blades.

Additional features

Consider features such as a sturdy metal base plate for stability, dust extraction or a brushless motor to maintain cleanliness and ergonomic handles for prolonged, low-vibration use. With the right blade, power, and speed settings, a heavy-duty jigsaw can cut through mild steel sheets, pipes, and plates up to 6mm thick.

Tips for cutting metal with a jigsaw

To cut metal with a jigsaw, the proper techniques and precautions must be followed:

Marking the cut line

Using a pencil or permanent marker, measure and mark the line you intend to cut on the metal. For cutting curves or complex shapes, consider using a template or stencil. It's imperative to secure the metal in a vice or using clamps to prevent it from slipping during cutting. Additionally, wearing safety glasses is vital to protect your eyes from metal shards and sparks.

Lubricating the blade

To prevent overheating, reduce friction, and prolong the blade's lifespan, apply a lubricating cutting fluid, oil, or a wax stick to both the blade and the marked cut line. Be prepared to reapply lubricant as necessary throughout the cutting process.

Adjusting the speed and feed rate

Select a slow blade speed, typically around 2,000 RPM, and maintain a slow feed rate. Allowing the blade teeth to do the work will minimize jagged edges or tearing. Apply firm and even pressure as you cut, ensuring a consistent and controlled motion.

Maintaining blade contact

It's essential to ensure continuous blade contact with the metal. Lifting the jigsaw at any point can cause the metal to warp or bend, potentially damaging the blade. For tight curves, make relief cuts before cutting out the desired shape, and take extra care when navigating corners or changing direction.

With the proper preparation and adherence to these techniques, you can achieve clean and accurate cuts in sheet metal and metal plates using a standard jigsaw. Taking your time and prioritising safety will lead to the best possible results.